Case Studies

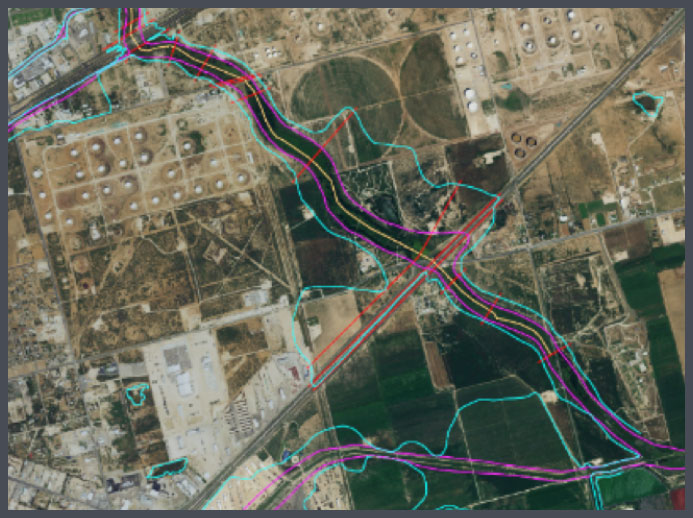

Case Study: As-built facility surveys for equipment addition/site reconfiguration planning

A major oil and gas operator in the DJ Basin was facing the challenge of updating thousands of their production facilities to comply with the Air Quality Control Commission’s (AQCC), a division of the Colorado Department of Health and Environment (CDPHE), revised air quality regulations. Regulation 7 was one of the many regulations that specifically impacted the oil and gas industry operations, by requiring 95% emissions control or greater for certain facilities and equipment. This was a difficult task for any operator, but a monumental one for the larger operators. The first challenge was getting an accurate picture of where sites were located, exactly, and equipment currently on location.

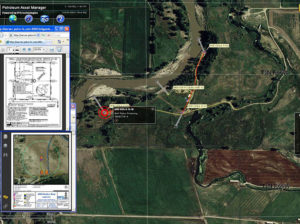

Ascent partnered with our client to lay out what needed to be done and how to best accomplish the tasks at hand. The client needed an accurate picture of not just what equipment they had at each production facility, but also the exact location and the amount of space occupied. Ascent answered all these questions through an as-built survey of all the client’s production facilities requiring updates. In addition to as-building all facility features and equipment, the current disturbance area was also mapped, which allowed the client to determine if the existing surface use agreement (SUA) would allow for facility expansion or if more space would be required. The data was then used to create site layout exhibits to help the client plan for expansion/reconfiguration, then utilized for creation of COGCC permitting exhibits to sundry any changes to the location. All collected as-built data was organized into a GIS database, attributed, and handed off to the client. There were many non-GIS users involved in the project that needed to track progress, and having constant access to data was key to the project success. So, Ascent built a customized Petroleum Asset Manager website to host all this data and display progress. Every day as new facilities were as-built, the data was loaded into the enterprise GIS database and instantly available on the website. The website displayed the estimated locations of all facilities (pre-as-built) and also the completed (actual) locations, with all associated equipment, therefore serving as a planning tool in additional to a tracking tool.

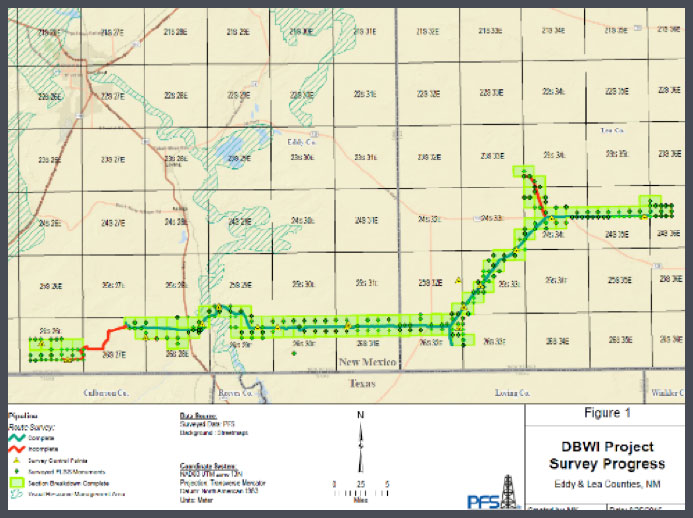

Case Study: Midstream Operator

A major independent midstream operator requested a boundary survey, facility location placement and BLM recordable right of way (ROW) exhibits for a 70 mile pipeline running through 56 sections of Federal BLM land. The project required extensive title research for undocumented existing utilities such as pipelines. The project was in a remote high desert location and required experienced crews and enhanced communication among team members.

Within 2 weeks’ the survey crews had completed the boundary survey of 56 sections by locating 224 monuments and placing the pipeline facilities within the required sections. Ascent then drafted the recordable ROW exhibits within the client’s timeframe and worked with the title company to provide all additional information requested to complete the title work. After the ROW exhibits were completed the client changed the routing of the pipeline and Ascent facilitated preparing the exhibits for the re-routing.

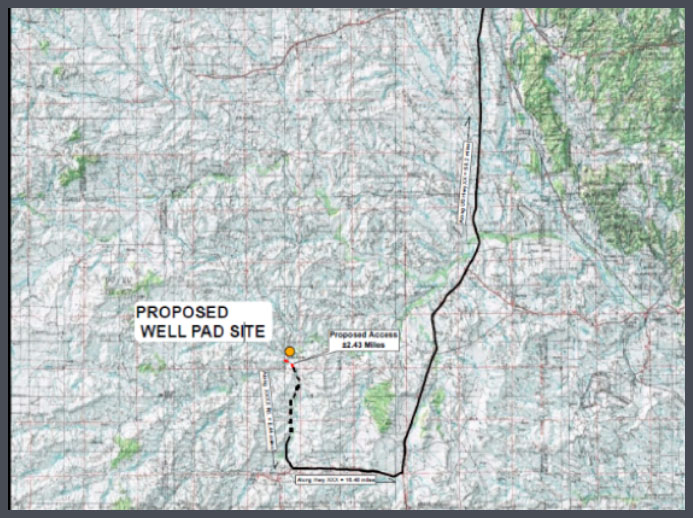

Case Study: Oil and Gas Operator

An oil and gas operator requested that we collect survey and topographic data so that they could determine which of two options for developing a road crossing an existing waterway would be better for existing pipelines and waterway channels. The surveying and mapping included multiple cross sections at each of the two locations.

The data collected allowed us to model each option and gave the client the information needed to understand the impact of each alternative on the floodplain and make a decision. The client made a decision and then asked us to permit the oil and gas facility being serviced by the new roadway which was successfully completed.

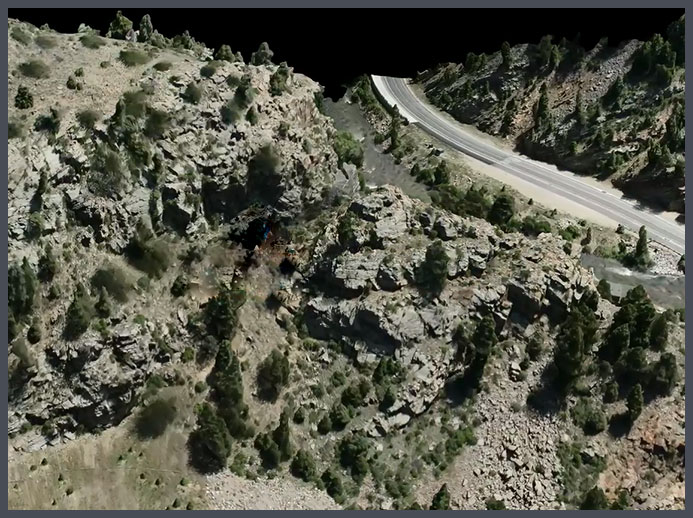

Case Study: Infrastructure

A geophysical consulting group requested updated photogrammetry by UAV and terrestrial LIDAR scan of a potentially unstable rock cropping along I70. The site was in a deep ravine along Clear Creek with heavy traffic on I-70.

Ascent deployed two teams to collect the aerial imagery, conduct high definition scans and establish the control network with RTK GPS. Sufficient data for thorough analysis was captured in one day and it was processed through PIX4D to create a DSM so that a mesh could be generated for photorealistic modeling. This data was used by the client to successfully analyze the joint and fracture planes in the rock for potential failure zones.

Case Study: Intersection Improvement

CDOT needed updated aerial imagery for initial design and scoping for intersection improvements in region 4. They also needed the imagery to be spatially accurate to integrate into their Microstation drawings for design and planning. This specific intersection was important due to there being a school crossing, heavy oil field traffic, and right down the road from a major intersection, being Highway 85 and Highway 66.

Traditional intersection surveys involve the surveyor going out into the road to collect features such as manholes and striping. Ascent utilized a 3D scanning unit to collect full detail of the intersection, without having to send any person into the middle of a busy highway. This thorough and safely collected data was married with aerial imagery captured by our UAV, giving the deliverable a geospatially accurate and colorized representation of the intersection, for design. Ascent utilized CDOT coding and processes to create a final Field Book deliverable containing points, line work, and layering that CDOT will be able to use for placement and design of cross walks, overlay, and signalization within a school zone. Ascent was able to collect incredibly accurate data from both the ground and air to create a detailed deliverable in less time, and a safer method, than it would have taken a traditional surveyor.

Case Study: Production Facility Construction and As-Built Survey

Our client was a growing operator in the DJ Basin in Colorado and was hiring professionals with many different skills in the oil and gas industry. The new Construction Foreman had his own vision of how these facilities would be built and saw the need to have the production facilities staked in advance of equipment and flowline installation using survey grade accuracy. With the evolution of large well pads with up to 24 producing oil and gas wells, the production facility design was sure to be very complicated and would require staking of hundreds of points for construction crews. Construction of facility pads is very quick and can result in short notice for initial and restaking of the pads meaning that field crews would be on call and ready to respond to the aggressive needs of the client.

Ascent met with the Construction Foreman prior to the build of new production facility pads to strategize on how to best meet the timelines and needs of the client. The Construction Foreman provided initial layout drawings of the facilities which Ascent then calculated points and checked safety setbacks to ensure an accurate and safe design. Each day of a new facility build, Ascent was in constant communication with the construction foreman to plan and execute the staking of facility equipment (separators, tanks, vapor recovery units, vapor recovery towers, emission control devices, sale meters, etc…) and the underground flowlines to connect everything together. After the production facility build was complete, Ascent then as-built all placed equipment and provided detailed drawings of each for the client’s reference. Throughout the process of multiple builds, Ascent was always available when the client requested services. Ascent is consistently assisting in the builds of additional production facilities for this client.

Case Study: Floodplain Analysis

The Midland Draw floodway runs along a roughly four mile stretch south of town on a northwest bearing. As a natural water drainage route, the draw contains dense vegetation and canopy cover through the center of the channel. In order to develop an accurate surface model for flood analysis, the client requested that Ascent capture topographic profile data at specified intervals, as well as existing infrastructure (bridges, highway, road, and rail) information.

Using Trimble R-10 rovers connected to network RTK (VRS), Ascent’s crews traversed 16 floodplain cross sections, the longest of which spanned 4300’. Using the Leica P-40 scanner, the crews then captured point clouds (4-8 scanner setups) at each bridge, elevated roadway, and rail line that crossed the study area. The entirety of the collected data was post-processed, merged, and submitted to the client for floodplain modeling and analysis.

Case Study: Permitting of Oil and Gas Locations and Wells

During the spring of 2014, activists in Colorado had proposed a ballot measure that could have had serious negative impact to the oil and gas industry by requiring greater setbacks for drilling locations, up to a 1/2 a mile from buildings. The DJ Basin is a congested and populated basin in general, and our client had a significant amount of acreage that would become largely undrillable should the ballot measures pass. Permitting in Colorado is already challenging, and even state permits can require 90+ days for approval during busy times. This new client in the DJ Basin had aggressive permitting and drilling goals to accomplish in 2014.

Ascent created a dedicated team consisting of a project manager, survey teams, PLS/PE, Engineering technicians, and Regulatory technicians. This multidisciplinary team was devoted solely to our client for a 2 month period and worked to get over 300 wells surveyed, exhibits drafted, and permits submitted. In just 10 days, the engineering team created over 300 well certificates and proposed spacing unit exhibits in order to allow the regulatory team to prepare and send thousands of surface and mineral owner notifications in order to start the permitting process. Under direction of the client, our regulatory group permitted 125 wells on 11 pad sites from July to December 2014, and permits were approved by the COGCC in 5 weeks or less. In conjunction with the client, Ascent is still permitting the remainder of the wells staked and continuing to permit new locations in 2015.

Bio coming soon.

Bio coming soon. Hold for Lisa McCool bio.

Hold for Lisa McCool bio. Hold for Christie Petersen bio.

Hold for Christie Petersen bio. Scott Bass manages all Colorado survey crews at Ascent. He began at Ascent in 2019, and has a variety of skills, including GPS and Conventional field survey locations, AutoCAD Drafting, Revit drafting, Bid Package Preparations, Directing Operations, Business Development, Project Budgeting, and Deed Research/Analysis.

Scott Bass manages all Colorado survey crews at Ascent. He began at Ascent in 2019, and has a variety of skills, including GPS and Conventional field survey locations, AutoCAD Drafting, Revit drafting, Bid Package Preparations, Directing Operations, Business Development, Project Budgeting, and Deed Research/Analysis. Hold for Matt Morris bio.

Hold for Matt Morris bio.

Chief People Officer

Chief People Officer Ramsey joined the Ascent team in November of 2017 and is CFO, as well as overseeing the Accounting, Finance, IT and Operations functions of Ascent. Ramsey brings more than a decade of finance experience across multiple disciplines including budgeting, FP&A, M&A, controllership, pricing and contract negotiations and treasury management.

Ramsey joined the Ascent team in November of 2017 and is CFO, as well as overseeing the Accounting, Finance, IT and Operations functions of Ascent. Ramsey brings more than a decade of finance experience across multiple disciplines including budgeting, FP&A, M&A, controllership, pricing and contract negotiations and treasury management. Founder

Founder Chief Executive Officer

Chief Executive Officer Regulatory Manager

Regulatory Manager Director of Innovation

Director of Innovation Chief Operating Officer

Chief Operating Officer Jerry has more than 30 years of technical and project management experience in the field of land surveying. As a retired Colorado Department of Transportation (CDOT) employee of 30 years, he brings his knowledge of CDOT procedure and techniques to the team. He is involved in the day to day process, procedures, and workflows of the infrastructure related projects, project phase and tasks, and verifying the delivery of survey data for the infrastructure projects. Primary functions include the QA/QC of daily and final survey deliverables, project management, researching Right of Way records, ensuring Federal, State, County, and Local requirements are met, and the signing and sealing of survey related documents for recording. Jerry has been a licensed Professional Land Surveyor in Colorado since 1994.

Jerry has more than 30 years of technical and project management experience in the field of land surveying. As a retired Colorado Department of Transportation (CDOT) employee of 30 years, he brings his knowledge of CDOT procedure and techniques to the team. He is involved in the day to day process, procedures, and workflows of the infrastructure related projects, project phase and tasks, and verifying the delivery of survey data for the infrastructure projects. Primary functions include the QA/QC of daily and final survey deliverables, project management, researching Right of Way records, ensuring Federal, State, County, and Local requirements are met, and the signing and sealing of survey related documents for recording. Jerry has been a licensed Professional Land Surveyor in Colorado since 1994. Program Manager

Program Manager

Bob has more than 40 years of experience in the surveying and mapping professions. He has worked in the capacity of owner, survey manager, office manager, and project manager for surveying, construction and engineering firms. As a Professional Land Surveyor, he has experience working on survey projects involving Primary control layout, construction, boundary, mining, oil-gas, topographic, and design. He has provided these services to a variety of clients including CDOT, Arapahoe County, Jefferson County, Clear Creek County, City and County of Denver, private engineering firms including CH2M Hill, Carter Burgess, J.F. Sato, Merrick & Co, Washington Group, Nolte Associate, and construction companies including Johnson Brothers Construction, Ames Construction Co., Sema Construction Co., KiewitWestern Construction, Kelly Construction and Lawrence Construction Co. Bob has been a Licensed Professional Land Surveyor since 1983, and holds an Associate Degree in Surveying from Red Rocks Community College.

Bob has more than 40 years of experience in the surveying and mapping professions. He has worked in the capacity of owner, survey manager, office manager, and project manager for surveying, construction and engineering firms. As a Professional Land Surveyor, he has experience working on survey projects involving Primary control layout, construction, boundary, mining, oil-gas, topographic, and design. He has provided these services to a variety of clients including CDOT, Arapahoe County, Jefferson County, Clear Creek County, City and County of Denver, private engineering firms including CH2M Hill, Carter Burgess, J.F. Sato, Merrick & Co, Washington Group, Nolte Associate, and construction companies including Johnson Brothers Construction, Ames Construction Co., Sema Construction Co., KiewitWestern Construction, Kelly Construction and Lawrence Construction Co. Bob has been a Licensed Professional Land Surveyor since 1983, and holds an Associate Degree in Surveying from Red Rocks Community College. Productions Manager

Productions Manager Engineering Manager

Engineering Manager GIS Manager

GIS Manager Senior Field Coordinator/Crew Chief

Senior Field Coordinator/Crew Chief Colorado

Colorado Data Processing Specialist

Data Processing Specialist Controller

Controller

Upstream oil & gas operators have one simple goal: find and drill hydrocarbons. To do this, operators must navigate the regulatory gauntlet to receive their necessary permits. Without the proper expertise and experience, operators can lose valuable time and possibly even lose the location itself to another operator.

Upstream oil & gas operators have one simple goal: find and drill hydrocarbons. To do this, operators must navigate the regulatory gauntlet to receive their necessary permits. Without the proper expertise and experience, operators can lose valuable time and possibly even lose the location itself to another operator. Extended Text for Popup: The ability to manage all your assets is critical to running an efficient organization. Having the ability to view floodplain, wildlife and/or utility lines can help operators better plan their sites for Surface Use Agreements (SUA).

Extended Text for Popup: The ability to manage all your assets is critical to running an efficient organization. Having the ability to view floodplain, wildlife and/or utility lines can help operators better plan their sites for Surface Use Agreements (SUA). Viewing up-to-date aerial imagery can help save companies thousands of dollars by avoiding previously unforeseen challenges at the site location.

Viewing up-to-date aerial imagery can help save companies thousands of dollars by avoiding previously unforeseen challenges at the site location. Most oil & gas operators will create as-built drawings for their well pads, pipelines, facilities and any other construction related projects. ASCENT has completed thousands of as-built surveys and drawings for our clients. Our extensive experience has taught us the most efficient and cost effective ways to create these as-built deliverables.

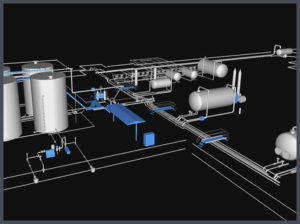

Most oil & gas operators will create as-built drawings for their well pads, pipelines, facilities and any other construction related projects. ASCENT has completed thousands of as-built surveys and drawings for our clients. Our extensive experience has taught us the most efficient and cost effective ways to create these as-built deliverables. When companies are looking to design, or modify a facility, there is no reason not to use LiDAR technology. LiDAR provides design-grade accuracy with 3D modeling to see how the facility will look after construction.

When companies are looking to design, or modify a facility, there is no reason not to use LiDAR technology. LiDAR provides design-grade accuracy with 3D modeling to see how the facility will look after construction. Pipeline projects can cost millions of dollars. Missing the project timelines can cost midstream operators even more money. That is why planning on the front-end of the project is so important.

Pipeline projects can cost millions of dollars. Missing the project timelines can cost midstream operators even more money. That is why planning on the front-end of the project is so important. Longer pipeline corridors can take a significant amount of time to create topographic surveys with traditional methods. With aerial LiDAR, ASCENT can significantly reduce the time it takes to create these topographic surveys while providing a tremendous amount of useful data. This highly accurate pre-construction LiDAR data can then be married with highly accurate after-built LiDAR data to determine the precision of the planned and constructed pipeline.

Longer pipeline corridors can take a significant amount of time to create topographic surveys with traditional methods. With aerial LiDAR, ASCENT can significantly reduce the time it takes to create these topographic surveys while providing a tremendous amount of useful data. This highly accurate pre-construction LiDAR data can then be married with highly accurate after-built LiDAR data to determine the precision of the planned and constructed pipeline.